Why You Need to Stop Buying Cheap Cutting Tools

You want to get the job done right and save costs, yet there’s a catch. Cheap cutting tools are appealing, but they come with consequences that can hurt your productivity in more ways than one. Quality metalworking tools might carry an upfront cost. However, if you factor it in over time, you’ll realize how wise of an investment this really is.

With proper care and maintenance, well-made cutting tools will last longer compared to their cheaper counterparts, giving you value for what you pay for!

There is no benefit in buying cheaply made tools, as they often need to be replaced more frequently and can pose a safety risk due to lack of control. This is why it is important to invest in quality tools from a trusted supplier. Their product range ensures reliability and quality for every tool purchased.

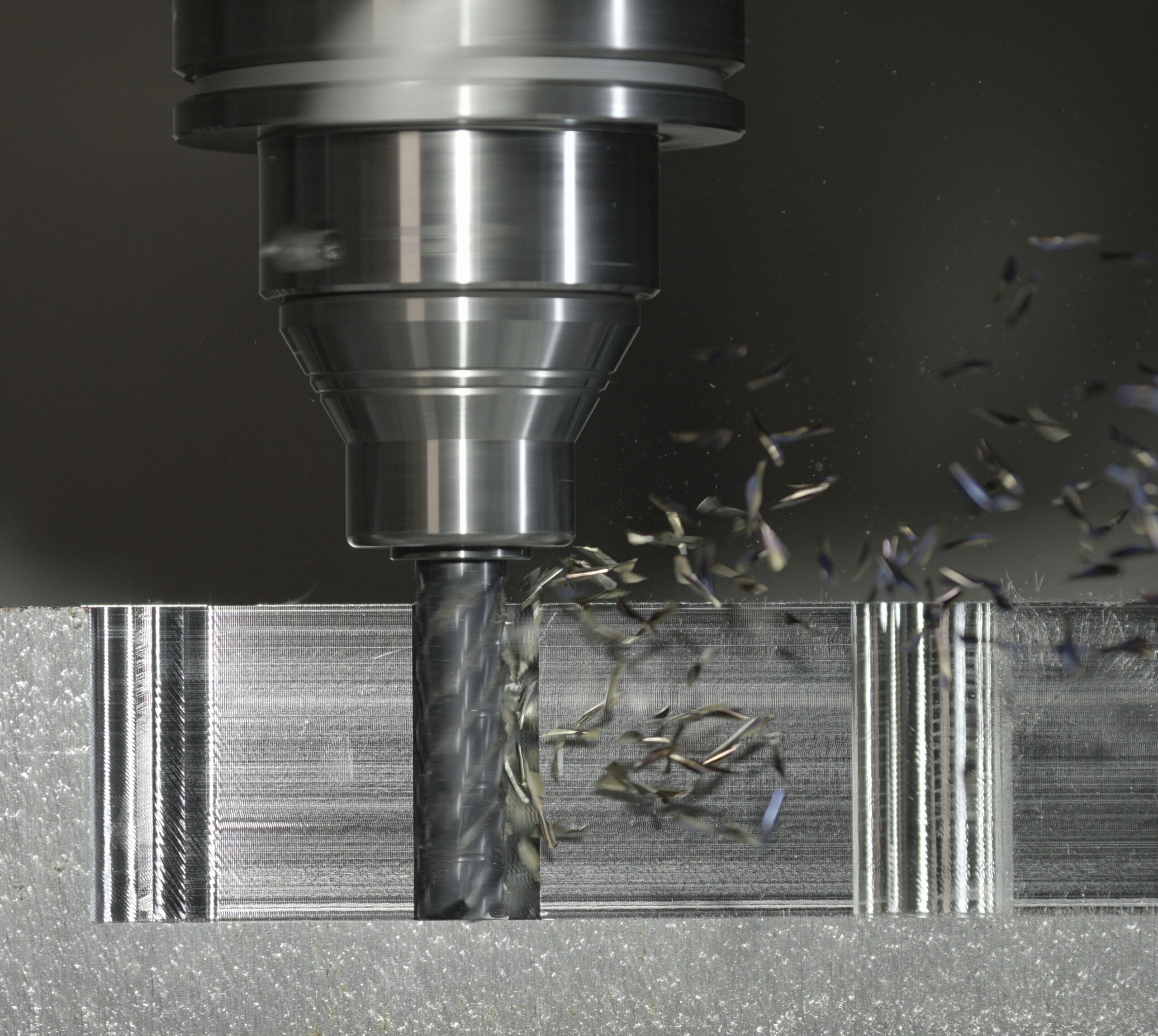

Poor Performance When Cutting

Are you considering technical-grade custom cutting tools to cut costs? If so, think again.

Poor-quality cutting tools can cause more harm than good as they often result in poor performance when used for various industrial applications. Cutting with substandard or cheap materials leads to excessive force on the tool, causing product inconsistencies and a decrease in the accuracy of the final product. The cost required for replacing these low-grade components is far greater than the savings initially incurred from buying them!

In addition, due to their inability to withstand prolonged use and wear and tear over time, reliability, durability, and safety are not guaranteed either. Furthermore, due to their lower hardness rating (relative to high-quality tools), rechargeability becomes nearly impossible, which further adds to your expenses, leaving you no option but to purchase new cheap tooling every time. Investing in quality custom fabrication is a surefire way of ensuring that you receive the best productivity from your equipment, with sharpening and durability being enhanced at an optimal level.

Unreliable Durability and Safety

When you purchase cheap cutting tools, there’s a good chance that the materials used to make them are of low quality. This directly impacts their durability and safety in three ways.

First, they will not be as hard or wear-resistant, which means more frequent sharpening and replacement is needed, thus increasing your need for additional tooling costs over time.

Second, if inferior metals such as aluminum alloy were used instead of tougher steel alloys, it may lead to premature failure. This is because, during cut operations, the inferior metals can easily bind together and cause broken pieces to fly off at high speed, which can result in serious injury.

Thirdly, cheaper versions often lack proper heat treatment, resulting in reduced toughness, reducing its ability to handle higher loads without breaking down, leading again to unplanned stops on the machining process, and harming product output volumes negatively.

In short, inadequate tooling leads to unreliable results when undertaking extensive production cuts.

Cheap cutting tools are less durable and vulnerable to repeated use, leading to a loss of productivity. Suncoast Precision Tools can offer you custom-made cutting tools that last longer while ensuring the desired accuracy in your project with their professional precision machining services. Moreover, they provide competitive pricing options, so you don’t break the bank when purchasing quality products.

Make sure when choosing metalworking equipment you choose wisely because not all cheap offers prove cost-effective in the long run! Investing in high-value, higher-priced cutters yields better outcomes for any business looking for reliable results and efficiency during production.