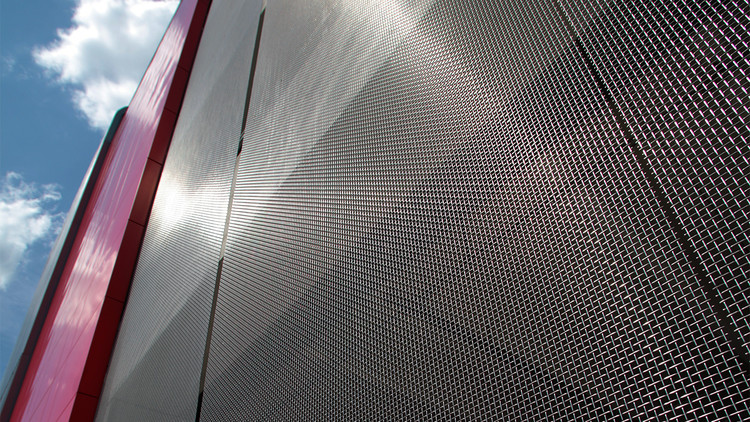

Fine wire mesh and its unique properties

Fine wire mesh is an incredibly versatile material that can be used in a variety of applications. From its most basic use – as a filter or sieve – fine wire mesh has found its way into the construction, manufacturing, and engineering industries. Its unique properties make it suitable for a range of tasks, from improving air and liquid flow to providing structural integrity to objects or materials.

Fine Wire Mesh – durability, flexibility, and corrosion resistance

Fine wire mesh is a unique type of material used in many industrial applications. It is made from multiple strands of metal wire woven together to create a net-like structure. The small openings between the wires and the strength of the metal make it very versatile and capable of performing in difficult conditions.

The properties that make this material so desirable include its durability, flexibility, corrosion resistance, and fireproofing abilities. Additionally, its lightweight characteristics allow for fast installation without requiring heavy machinery or specialized tools. Depending on the application, fine wire mesh can come in various sizes and shapes including circular, rectangular or even custom designs requested by customers.

Overall, fine wire mesh provides an excellent solution for businesses looking for a strong yet lightweight material that can withstand harsh conditions while still providing great results.

Benefits of Using Fine Wire Mesh

Fine wire mesh is a versatile material used for a variety of applications. It offers unique properties that make it an ideal choice in many industries.

Fine wire mesh has numerous advantages over other materials due to its durability, flexibility, and cost-effectiveness. Its strength and ability to withstand harsh conditions make it ideal for industrial projects such as filtration systems or security fences. Additionally, its flexible nature makes it easier to shape into intricate designs while still maintaining its structural integrity. For those looking to reduce costs without sacrificing quality, fine wire mesh could be the perfect solution, since it requires less material than traditional methods like welding or riveting.

Types of Fine Wire Mesh

Fine wire mesh is a versatile material with many unique properties. It is made from a combination of fine wires, often stainless steel or other metal alloys, that are woven together to create an open texture for a variety of applications.

The most commonly used type of fine wire mesh is plain-weave stainless steel. This type features evenly spaced wires that form a tight grid pattern and provide excellent strength and durability in both low and high temperatures. Another type is a Dutch weave, which has fewer cross-wise threads but more lengthwise threads to create a denser, stronger material with more resistance to abrasion. Twilled Dutch weave provides additional strength while still allowing airflow and water draining capabilities when used as screening materials.

Applications of Fine Wire Mesh

Fine wire mesh has a wide range of applications – from industrial engineering to everyday household items. It is an extremely versatile material, possessing unique properties that make it invaluable for many types of uses. This article explores the different ways fine wire mesh can be used and its advantages over other materials.

The small size of fine wire mesh makes it ideal for filtration, sieving, and separation applications. Its intricate webbing allows it to trap particles while allowing liquids and air through in certain circumstances. Therefore, fine wire mesh is often used in water treatment plants to filter out unwanted contaminants such as dirt and dust before they are released into the environment. Additionally, it can be used in laboratories as laboratory strainers or sieves when conducting scientific experiments or research tests.